TIG Welding

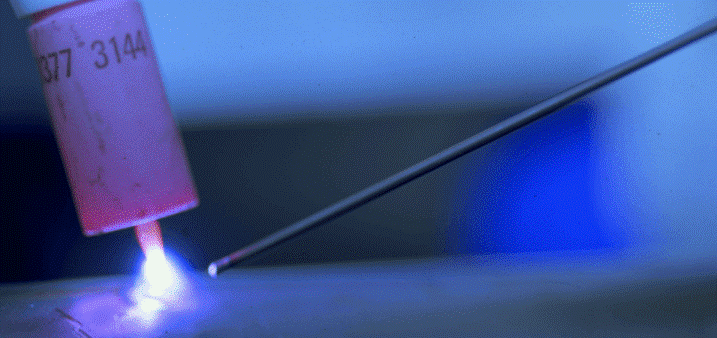

Tungsten Inert Gas (TIG) welding uses the heat generated by an electric arc struck between a non-consumable tungsten electrode and the workpiece to fuse metal in the joint area and produce a molten weld pool. TIG welding produces temperatures up to 35,000 degrees Fahrenheit, yet this concentrated heat can be precisely controlled and directed. When filler metal is required, it can be added manually by feeding welding rod into the puddle, similar to oxyacetylene welding. In fact, oxyacetylene welders usually pick up TIG welding fairly easily.

TIG welding applications

TIG welding is a highly practical skill with various applications. TIG is the most versatile type of welding and can be used on steel, bronze, titanium, copper, aluminium, stainless steel, Chromoly, nickel alloys, magnesium, brass, and gold.

TIG is a useful process for welding

- Bike frames

- Pipe welding

- Wagons

- Lawnmowers

- Airplanes

- Automobiles

- Medical and scientific equipment

Features of TIG Welding

- A non-consumable tungsten rod is used in TIG welding

- If required, Filler metal can be added manually.

- Shielding gas helps in protecting the weld and tungsten

- High quality and clean welds are achieved.

- TIG welding allows welding of more metals than any other process.

TIG welding FAQ

- Titanium and steel.

- Aluminum and copper.

- Aluminum and stainless steel.

- Aluminum and carbon steel.